MDM-Die Casting Technology Co.,Ltd. is a professional die casting manufacturer. The company is located in Shishan TownNanhai district specializing in the production of aluminum alloy die casting,zinc alloy die casting,magnesium alloy die casting

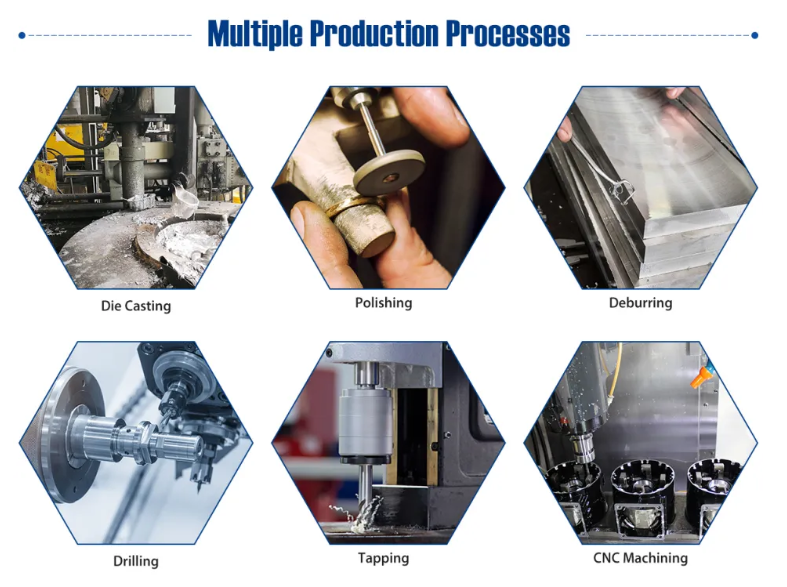

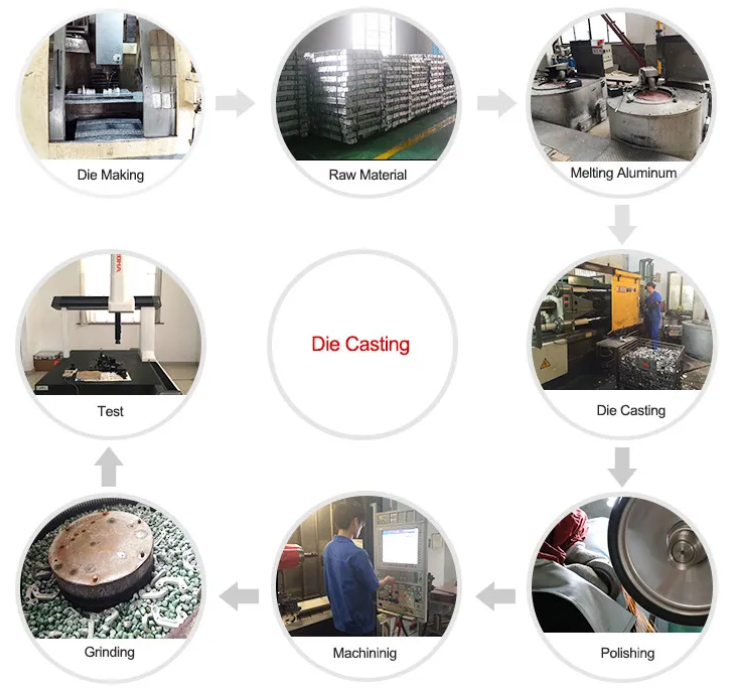

Yes, those are all different metal production processes. Here's a brief description of each:1. Die casting: A process where molten metal is injected into a mold under high pressure to produce a part with a specific shape.2. Polishing: A finishing process that involves smoothing or shining a metal surface by using abrasive materials or buffing wheels.3. Deburring: The removal of burrs, or rough edges, typically left over from machining or cutting operations. Deburring can be done manually, but there are also machines that automate the process.4. Drill tapping: A process where a hole is drilled into a piece of metal and a threaded tap is used to create threads in the hole.5. CNC machining: A process where a computer-controlled machine (such as a lathe or milling machine) is used to remove material from a piece of metal to create a specific shape or surface finish.

Metal surface treatment involves modifying the surface of a metal to achieve certain characteristics such as improved appearance, corrosion resistance, wear resistance, and adhesion. There are several methods of metal surface treatment including:1. Plating - The process of electroplating deposits a thin layer of metal onto the surface of another metal to improve its properties.2. Painting - Applying a coat of paint or enamel to protect the metal from corrosion and give it a decorative finish.3. Anodizing - A process that creates a protective oxide layer on aluminum, which improves its corrosion resistance, increases its hardness, and provides a surface for dyeing.4. Passivation - This process involves treating the surface of stainless steel to remove any free iron, which can cause rusting, and to improve its resistance to corrosion.5. Shot blasting - A process used to clean and prepare metal surfaces for further processing by blasting them with small metal particles at high speed.6. Galvanizing - A process that involves coating steel with a layer of zinc to protect it from corrosion.7. Powder coating - A type of coating that is applied as a dry, free-flowing powder to metal surfaces and then cured under heat, creating a hard, durable finish. These surface treatments can be used alone or in combination with each other to achieve the desired results.

Years of rich professional experience,robust team technology and quality assurance system<

With years of service and supporting experience<

Flexible, fast and all-round to meet customer needs<

Flexible, fast and all-round to meet customer needs<

Top metal parts supplier is at your service

If you want to customize metal parts for your own brands, or purchase for your projects, please leave a message here, we will send our quotation and arrange the delivery of free samples as soon as possible.

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.